RTX Tips

Maintenance · Information · Technology · Guides

Being around rubber tracks, tires, and undercarriage parts for over twenty years has allowed us to accumilate a lot of knowledge about not just the parts we sell, but the machines they go on. RTX Tips is our way of sharing that knowlwdge with you. You'll find everything from deep dives into the technology that goes into our products, to proper care and service tips, to fun facts and information. We hope you will enjoy these articles as much as we enjoyed making them and maybe even learn a thing or two along the way.

Recent Articles

Getting the Most Mileage out of your Rubber Tracks

Regular maintenance and proper driving techniques can really help extend the life of your rubber tracks....

Understanding your CTL Suspension and Undercarriage System

Compact track loader operators have been spoiled over the past few years as more....

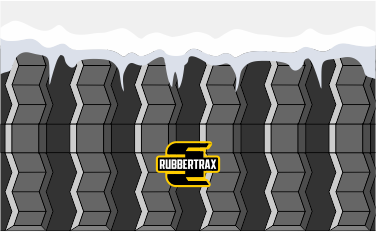

Zig-Zag: The King of Snow Friendly Tread Patterns

It's the best way to go if you need maximum traction and reduced vibration....

Showing your undercarriage some love

It's no secret that reducing wear on your machine's undercarriage will extend the life of your parts....

What’s up with the colorful rubber tracks?

Typically a rubber track appears to black much like a skid steer tire or even a truck tire...

Differences in MTL Widths and Lug Counts

Are you confused by all of the different width options and how many drive lugs are on your multi-terrain loader...